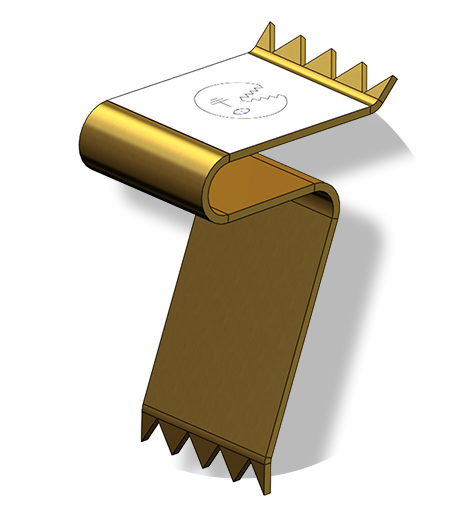

The TerraGrif™ is a metal spring-toothed blade, positioned between the module and the mounting structure, ensuring the optimum equipotential bonding of a photovoltaic installation.

All Terragrifs ™ are studied and realized according to the mounting system and photovoltaic panels.

All TerraGrif™ products are tested by the VERITAS LCIE according to a protocol established in line with currents standards: CEI 61730-2 + A1, IEC 60439-1 – § 8.2.4.1 and NF EN 60068-2-11. Photovoltaic panel frames are anodized and have a resistance in the region of 20 MOhm. They are characterized by a variable frames depending on the manufacturers.

Conventional earthing consists of solutions considered by professionals as being restrictive and ‘not practical’, which have the following characteristics:

Now “WITH” Terragrif™

The Terragrif™ is designed and produced according to the mounting structure implemented and depending on the various photovoltaic panels used.

The Terragrif™ is in contact with the frame, either by being pressed or interlocked. During the implementation, this interlocking is facilitated by the shape and geometry of the claws, and has several functions.

Tested and approved by LCIE BUREAU VERITAS (test report available)

more detailsThe VERITAS LCIE certification protocol subjects the Terragrif™ to 3 constraints:

The results are considered as satisfactory, only if the value of the resistance during these 3 tests is less than 50 mOhm.

In the various tests, all of the Terragrif™ products obtain a value of between 5 and 10 mOhm. The standards are largely met and even exceeded.

The report on these LCIE tests is available upon request. Do not hesitate to contact us.

The Terragrif™ ensures the absence of induced loops and provides you with an optimum level of safety.

Save 80% time on your earthing installations!

more detailsAssembly and disassembly for maintenance and/or panel inspection

more detailsDuring the installation of photovoltaic panels, the Terragrif™ is positioned between the module and the mounting system. On some installations and depending on the technical features, some claws are designed for implementation after the modules have been installed.

Reduce the material used for PV earthing

Terragrif™ equips 90% of existing mounting systems

more detailsCompatibility and production

MOBASOLAR has developed specific Terragrif™ products which are compatible for more than 90% of mounting systems.

Among others, Terragrif™ products are compatible on the following mounting systems:

This list changes and is therefore not exhaustive.

All Terragrif™ products are manufactured in France: from the design to the manufacture of the parts (small and large quantities).

No pressure on glass

Ensure optimum level of safety on installations

Reduction of 500 tons of copper

total at end of service life